Modern transportation places increasing emphasis on extreme lightweight design to improve fuel efficiency or electric driving range, while simultaneously increasing payload capacity. Reducing vehicle weight has become a key objective in both conventional and new-energy commercial vehicles. Replacing traditional metal structures with advanced composite materials is one of the most effective approaches to lightweight construction. Among these solutions, cargo bodies for trucks and trailers built with fiberglass honeycomb panels represent a typical and proven lightweight structural application.

What is fiberglass honeycomb panel?

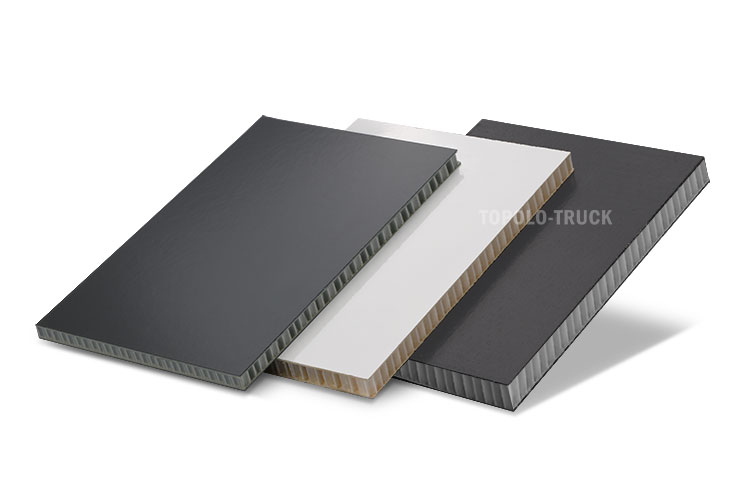

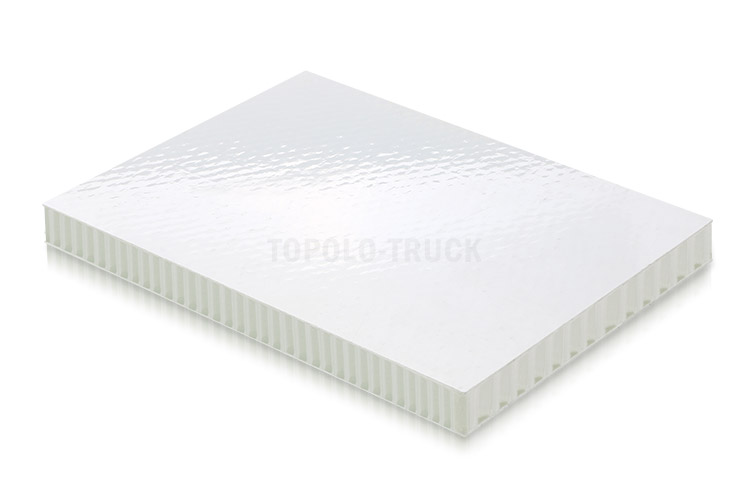

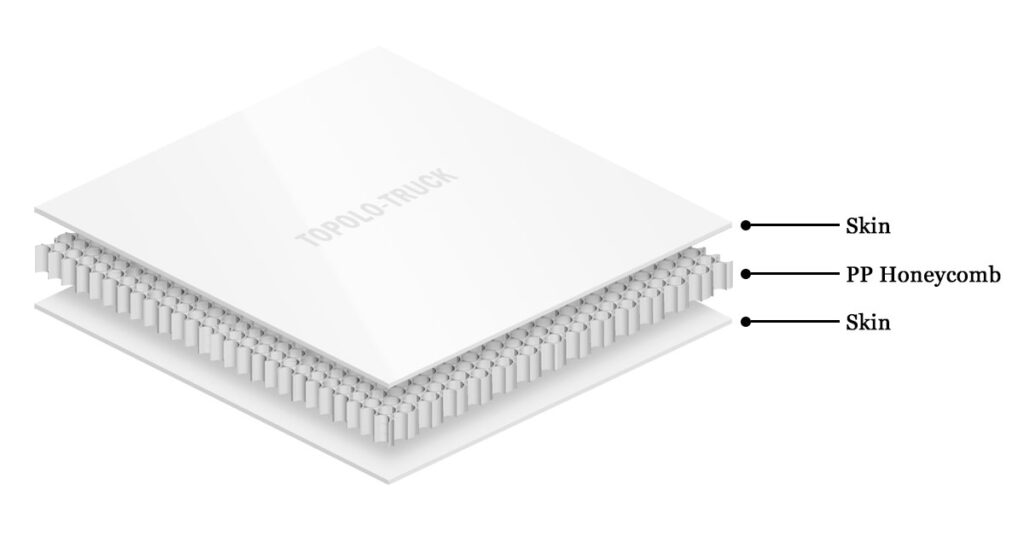

Fiberglass honeycomb panel is a high-performance sandwich material composed of fiberglass-reinforced panels and a polypropylene honeycomb core. Through the mechanical advantages of the honeycomb structure, it achieves excellent structural rigidity and load-bearing capacity at extremely low densities.

Its core advantages include:

☑ Lightweight design

Significantly reduces vehicle weight and improves transportation efficiency.

☑ Thin structure

Saves space and increases the effective volume of the cargo compartment.

☑ High compressive strength and rigidity

The honeycomb core structure effectively disperses external forces.

☑ Moisture-proof and corrosion-resistant

Suitable for various complex transportation environments.

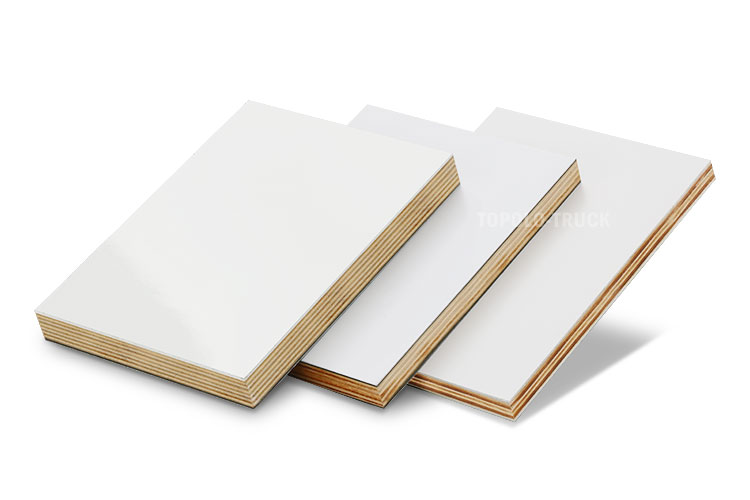

Common Fiberglass Honeycomb Panels for Cargo Bodies

Honeycomb Panel Cargo Box Structure

The cargo body structure based on fiberglass honeycomb panels adopts modular design for key components, making the entire assembly process more efficient and quick, while also facilitating later maintenance and replacement. This not only improves production efficiency but also enhances overall consistency and reliability.

- Side frame: Aluminum profile, connected by welding.

- Bottom beam: Galvanized steel, connected to the side frame with screws.

- Box Panel: Fiberglass PP honeycomb panel, connected with the aluminum frame by rivets.

Stability and Reliability

Lightweight design does not mean sacrificing structural strength. On the contrary, when cargo inside the box experiences impacts during transportation, the honeycomb structure can absorb the shock energy through its unique elasticity and buffering properties, allowing it to rebound effectively. This process not only protects the cargo body from damage but also significantly reduces the risk of cargo damage, thus enhancing both safety and durability.