The truck or trailer body structure is disassembled into standardized, independently manufactured functional modules (such as front wall assembly, side wall assembly, tailgate assembly, bottom frame crossbeams, etc.), enabling rapid assembly and flexible configuration through universal interfaces (riveting, high-strength bolts, etc.). Unlike traditional integral welded or molded body structures, its core characteristic lies in the flexible logic of “disassembly – combination – adaptation.” This design concept is similar to “industrial Lego,” allowing for functional adaptation through modular combinations, from small light-duty truck cargo bodies to heavy-duty modular transport vehicles over ten meters long.

☑ Modular Units

Each module serves as an independently manufactured functional unit while maintaining a standardized interface.

☑ Standardized Connections

Removable connection methods such as riveting or bolting replace traditional welding, ensuring both structural strength and maintenance flexibility.

How does TOPOLO-TRUCK achieve modular production of box bodies?

As an industry leader, TOPOLO-TRUCK implements modular box bodies through a “Design – Materials – Process” integrated technology system.

Ingenious Design

The box body is divided into core modules such as the front panel, side panels, floor, and tailgate, with each module pre-equipped with standardized connection holes and positioning structures.

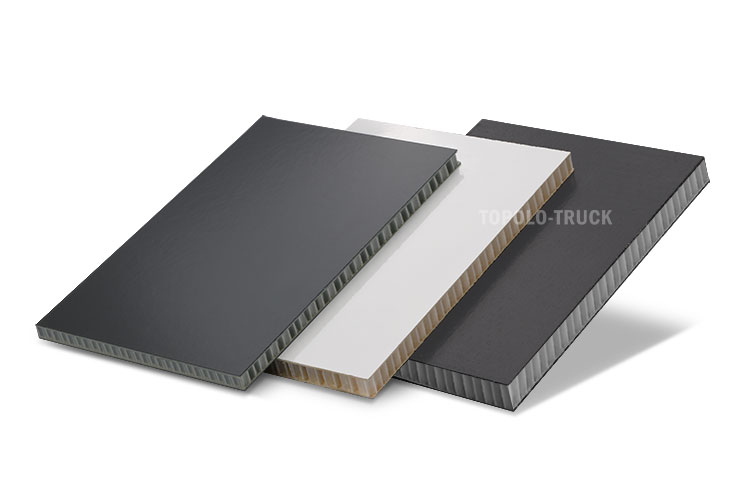

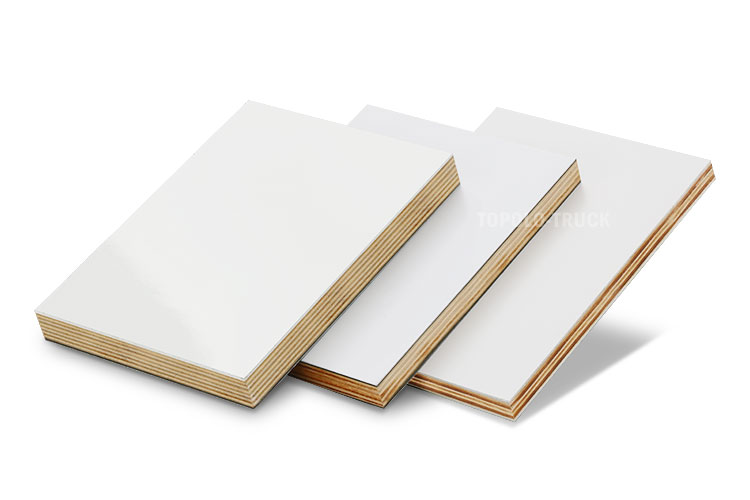

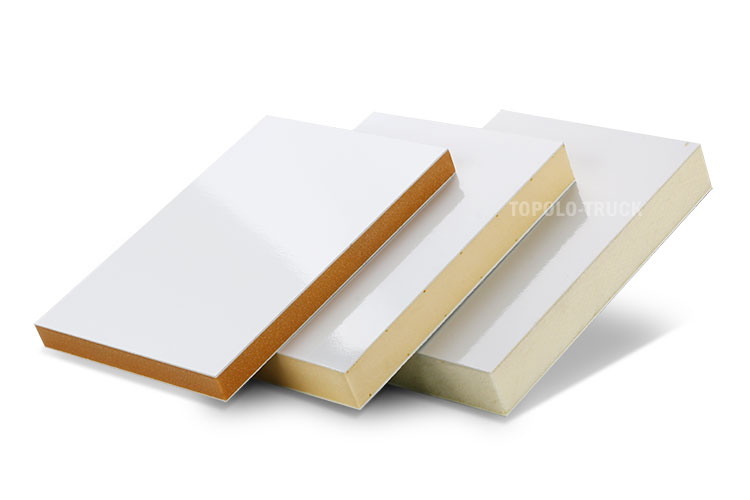

Composite Materials

Extensive use of advanced composite materials is a prerequisite for achieving modular box bodies. Glass fiber-reinforced sandwich panels serve as the core material system, enabling solutions for multiple scenarios, including refrigerated, insulated, and dry cargo applications.

Pre-Assembled Kits

Box body module kits are manufactured in the factory, and the CKD (Completely Knocked Down) / SKD (Semi-Knocked Down) delivery model allows customers worldwide to perform localized assembly.

Core Significance of Modular Box Bodies for the Industry

☑ Reduced Construction Complexity

Traditional box bodies rely on large welding equipment and skilled technicians, and welding errors can easily lead to misalignment or component failure. Modular technology reduces complexity through standardized components and simplified processes. Connections are primarily made using riveting or bolting. Once the components arrive on site, ordinary workers can assemble them with simple tools, without the need for welding certification.

☑ Improved Assembly Efficiency

Modular technology reshapes the production process through a “factory prefabrication + on-site assembly” approach, reducing assembly time by more than 70%. Over 85% of component processing is completed in the factory, leaving only simple assembly tasks on site. Components are transported in CKD (completely knocked down) or SKD (semi-knocked down) form, saving more than 60% of transportation space and indirectly shortening the supply chain cycle.

☑ Manufacturing Cost Savings

The standardized modular design not only enhances production efficiency but also significantly reduces manufacturing costs. By using uniform standardized components, material utilization can exceed 90%, effectively minimizing raw material waste and inventory pressure. Additionally, this design approach facilitates large-scale production, ensures stable production rhythms, and makes unit production costs more reasonable, greatly improving overall manufacturing cost-effectiveness.

☑ Easier Maintenance

Modular design makes maintenance simpler and more convenient. When a specific part fails, it can be repaired by replacing a single module without the need for large-scale disassembly or reconstruction of the entire body. This not only shortens repair time but also reduces maintenance costs.