Enhancing Refrigerated Transport Efficiency with Advanced Composite Panels

Choosing the right refrigerated box composite panels plays a key role in maintaining the required temperature for the cargo. These composite panels are designed to maintain the efficient operation of the refrigeration unit, providing insulation to prevent rapid heat loss. TOPOLO-TRUCK has leading manufacturing technology for modular insulation composite panels. It offers practical box panel solutions for many refrigerated truck and trailer manufacturers.

Specifications

| Composition | Wall panel. (Skin + Foam + Skin, thickness 50-150mm.) |

| Top panel. (Skin + Foam + Skin, thickness 50-150mm.) | |

| Door panel. (Skin + Foam + Skin, thickness 50-150mm.) | |

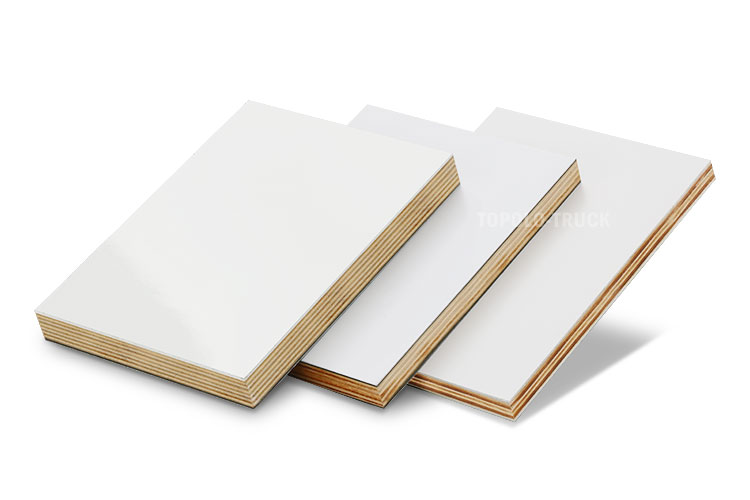

| Bottom panel. (Skin + Plywood + Foam + Skin, thickness 50-150mm.) | |

| Roof panel. (Skin + Foam + Skin, thickness 50-150mm.) | |

| Partition panel. (Skin + Foam + Skin, thickness 50-150mm.) | |

| Panel length | 2.8-13m. |

| Panel width | Maximum 3.2m. |

| Panel thickness | 50-150mm. |

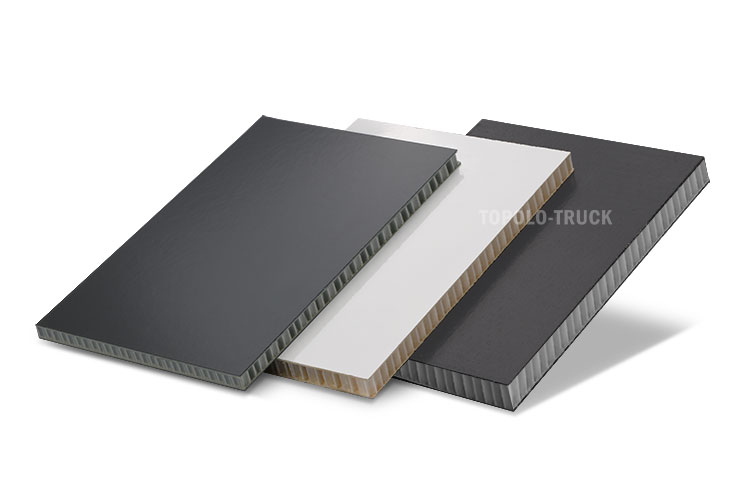

| Skin material | FRP(Glass fiber reinforced plastic) sheet. (Customized: 0.7~5.0mm). |

| CFRT(Continuous fiber reinforced thermoplastics) sheet. (Customized: 0.7~2.0mm). | |

| Core material | XPS (Extruded Polystyrene) foam. (Density: 35-50kg/m³) |

| PU (Polyurethane) foam. (Density: 28-50kg/m³) | |

| Frame materials | Timbers, fiberglass profiles, etc. |

| Processing method | CNC machining. |

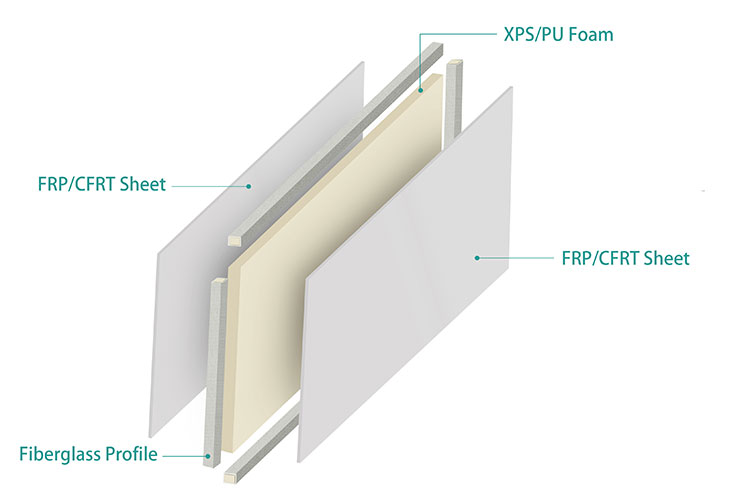

Integrated Composite Panels

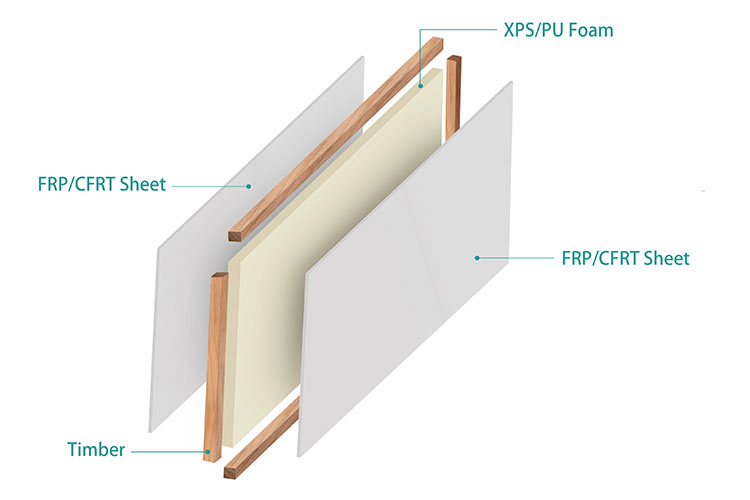

The integrated composite panel is formed by laminating fiberglass-reinforced surfaces, insulating core materials, and other additional materials in a press. Each side of the refrigerated box (except the door panels) is made of a single, seamless composite panel. This ensures the structural integrity and tight sealing of the box. The design of the composite panel significantly improves the insulation performance of the refrigerated box, while also enhancing its impact resistance, aging resistance, and suitability for use in various complex environments. Through this integrated manufacturing process, the refrigerated box achieves remarkable improvements in thermal insulation, lightness, durability, and energy efficiency.

Premium Raw Materials

Insulation Materials

- We use low thermal conductivity polyurethane (PU) or extruded polystyrene (XPS) foam as the core material. These materials offer excellent thermal insulation properties, helping to maintain a stable temperature inside the refrigerated box.

Fiberglass Reinforced Skin Materials

- We use antimicrobial-grade FRP materials, which have a smooth and flat surface, making them easy to clean. Additionally, we have developed a new type of FRP material—CFRT—which has several times the compressive and tensile strength of regular FRP, significantly enhancing the strength and durability of the panels.

Frame Materials

- We offer a variety of embedded structural components that can be customized according to the specific application requirements of the refrigerated box, enhancing the structural strength of the panels and improving overall stability and longevity.

Multiple Composite Panel Construction Solutions

- The panel uses a typical sandwich structure with a simple structure and is suitable for small reefer truck boxes that do not require high strength.

- The use of timber as the frame structure of sandwich panels can greatly provide the strength of the panels and provide sufficient connection support between panels. The excellent nail-holding strength of timber facilitates the installation of other accessories.

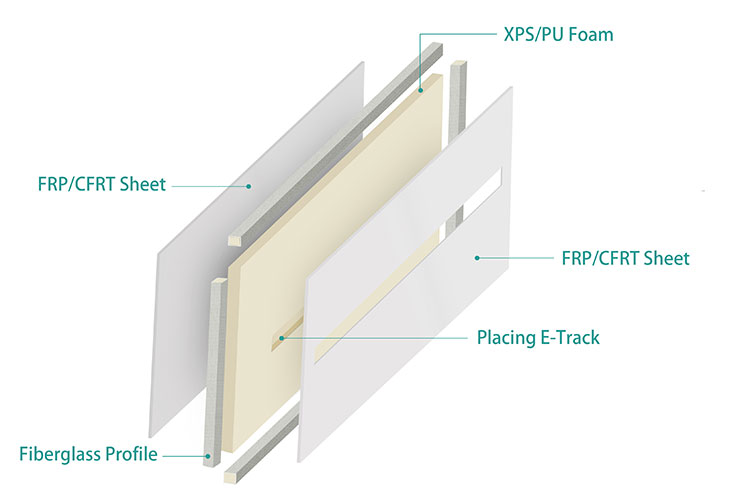

- Sandwich panels using high-strength fiberglass materials as frame structures are much stronger than sandwich panels with wood structures. Moreover, fiberglass parts do not absorb water, rot, or deform, and their normal service life can reach 20 to 30 years.

- It is developed on the basis of fiberglass frame structure sandwich panels, and E-Tracks are installed inside the sandwich panels. This advanced design method not only allows the E-Tracks to be installed more firmly but also keeps the surface of the reefer truck side panels smooth, reducing the risk of damage to the cargo and the E-Track system itself.

Advanced Composite Panel Manufacturing Technology

Fully automated high-speed cutting and rolling equipment.

large-area operating platform of 144 square meters.

Multi-layer vacuum press

High-precision 5-axis simultaneous CNC machining.

Fast-assembly Modular Structure

The integrated modular design of composite panels enhances the construction speed of refrigerated boxes, enabling large-scale production.

CKD/SKD kits

Assembly complete